This article aims to explain the language and terminology of supplier silo proposals and help interpret the most common units of measurement so you can make an educated comparison and an informed decision, because no matter what some people may think, a silo isn’t just a silo.

During a recent client meeting, I asked how my client compares competitive silo proposals. He told me he looks at price per pound (price/lb) because he assumed this metric was consistent across all proposals. Although price (or price/lb) is the factor most people use for comparison, it’s not necessarily the most important thing to consider when examining proposals. As we pointed out in our first article,1 it’s important to fully understand how your silo will be used over its effective service life.

During a recent client meeting, I asked how my client compares competitive silo proposals. He told me he looks at price per pound (price/lb) because he assumed this metric was consistent across all proposals. Although price (or price/lb) is the factor most people use for comparison, it’s not necessarily the most important thing to consider when examining proposals. As we pointed out in our first article,1 it’s important to fully understand how your silo will be used over its effective service life.

Heavy, industrial silos are typically manufactured for continuous use over 25 to 35 years, so factors like manufacturing quality, factory-applied coating systems reliability, and the supplier’s experience in designing silos for storing various materials are of critical importance. Examine each proposal you’re considering line by line above the listed price and make note of similarities or deviations in geometrical layout, building codes, and the size, shape, and quantity of accessories featured within the list price, as well as options added below the list price of each proposal. In particular, pay attention to the design criteria, material flow, silo style, additional expenses, coatings, pricing specifics, lead times, and supplier qualifications.

Design criteria. Currently, there is no unified standard in use for the design and manufacture of atmospherically vented storage vessels for the storage of dry bulk materials. Until the forthcoming AMSE- SBS (The American Society of Mechanical Engineers – Structures for Bulk Solids; release year is uncertain) is completed as and adopted for use across the industry, potential buyers will need to review a few different factors to ensure all vendor proposals are, in fact, “apples to apples.”

Geotechnical. The first variable you need to confirm is the documented building code standard used, such as IBC 2016 or whichever version the local/state building authorities recognize. IBC (US) and NBC (Canada) will provide various engineering values relative to environmental factors, including seismic values for earthquake analysis and other hazards. These values, along with wind/hurricane risk factors, generate relative minimum safety factors used in the structural design calculation of the silo being offered.

Most suppliers remain current with each geographical building code in the US and Canada. A few adhere to an older version and that could mean a difference in price.

If you have any doubt regarding structural or functional site classifications, as the owner, it will ultimately be your responsibility to present the compliant building plans to the permitting authorities. Failure to ensure that the proposed supplier’s equipment is in compliance can result in permitting delays and additional time required to resubmit corrected building plans.

Structural calculations. In order to determine the structural requirements to support the applicable liveloads (loads induced through movement of equipment supported on or in a silo) and dead-loads (stationary equipment, etc.), each vendor will take these factors and run through the Critical Buckling formula, from the book, Structural Analysis of Shells by Baker, Kovalevsky, and Rish. 2 The tank product area should be designed according to Janssen’s formulas for cylindrical bins, which are used to calculate the vertical and lateral pressures in a silo by the bulk solid material.

Material flow. The principles of bulk material flow are based on the methods of continuum mechanics. The silo engineers will utilize Janssen’s Formulas for Cylindrical Bins in order to calculate the vertical and lateral pressures imposed by the bulk solid material in that supplier’s suggested geometrical silo layout.

Material flow. The principles of bulk material flow are based on the methods of continuum mechanics. The silo engineers will utilize Janssen’s Formulas for Cylindrical Bins in order to calculate the vertical and lateral pressures imposed by the bulk solid material in that supplier’s suggested geometrical silo layout.

Ensure the silo is designed to accommodate the compacted bulk density of the stored material. Check that the hopper slope and discharge outlet diameter will promote the desired material flow. If mass flow (first-in, first-out) is critical to your application, ask how suppliers came to their suggested hopper configuration (hopper slope and outlet diameter). Mass flow testing can usually be done prior to making a decision on a silo supplier, and some will cover this cost within the proposal’s scope to help ensure you get what you require.

Do proposals list a similar quantifiable storage capacity as usable capacity, level-full capacity, or both? Compare the different geometrical configurations that can offer more efficient foundational layouts or height-to-diameter ratios (narrower & taller can help to reduce particle segregation in a funnel-flow design, for example).

Material explosivity. The Occupational Safety and Health Administration (OSHA) in the US defines combustible dust as “a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations.”

If your material falls under this definition, inspect and review each proposal’s design section or accessory list for reference to NFPA 68: The Standard on Explosion Protection by Deflagration Venting. Specifically, you should confirm that each references the KST and Pmax placement of these panels is symmetrical and confirm the supplier’s panel configuration to ensure that in case of a rupture in the panels due to an explosion, it will not vent in the direction of any other silo, building, or walkway.

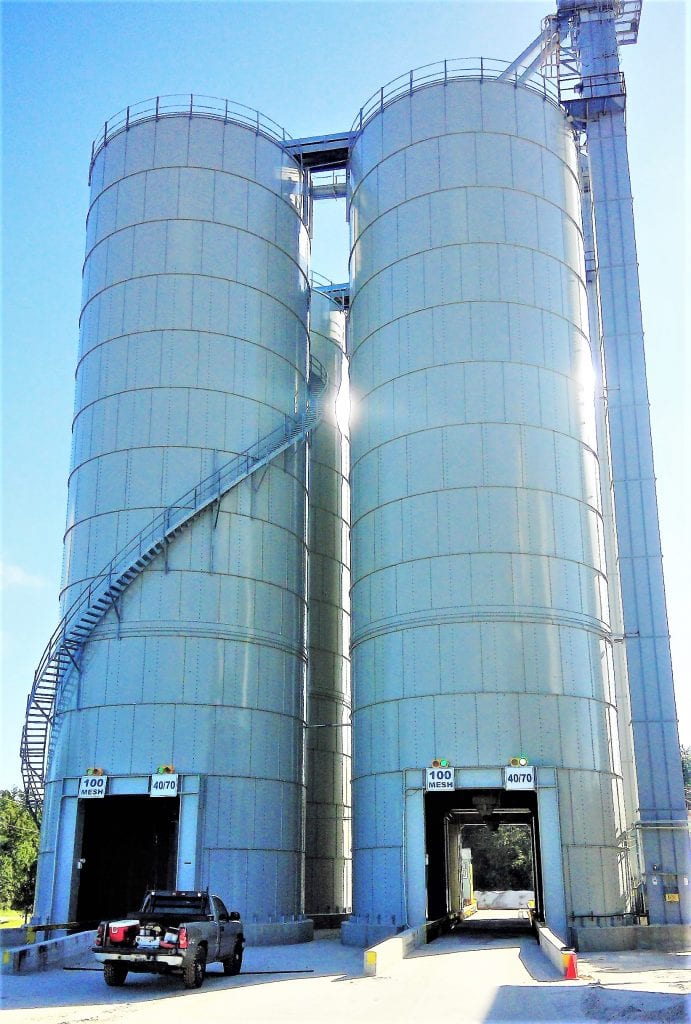

Silo style. Don’t get locked into the supplier’s suggested design just because they only offer one type of silo design and a specific construction method. For example, a flat-panel silo is erected with jacks 99.9 percent of the time, whereas a chime-panel silo is erected with scaffolding, and a welded silo ships from the factory in one piece. Most suppliers offer just one of the types listed, so, by default, they must make their silo and construction method fit your specific application. It’s important to understand why each potential supplier is suggesting that specific style of silo for your application and budget before proceeding.

Additional expenses. Identify items such as anchor bolts, structural reinforcement for truck drive-through, silo support structure, deck live/dead load design, or any other special additional accessories that may or may not be included in the proposal. Make sure it’s clear in the proposal if they’re listed as in scope or separately because that affects the total price and ROI.

If you look closely at the way the proposals are written, you’ll notice that some list all of the necessary accessories you will require, such as knife-gates, maintenance gates, truck-fill piping, special wear-resistant pipe-elbows, safety ladders, and cross-over platforms (whether you specified them or not), in their scope of supply. These suppliers have likely taken the extra time to understand your requirements and included these necessary accessories in the proposal for the benefit of your application. Conversely, others may try to make their quote look more attractive (for example, lower-cost price listed in bold or lower cost per pound) by listing these accessories below the price in bold as options the buyer can choose to add separately. The latter supplier either hasn’t taken the time to fully understand your needs or they’re assuming most clients will only look at the number in bold. While this quote looks like a better value, it can be misleading.

Make sure that what’s listed as “in scope” is truly included and confirm that every line item adds up. There are many ways to draft a proposal which means you should recognize these variables for what they are and proceed cautiously with the lower bid that doesn’t have all the necessary items listed or doesn’t detail what’s included.

For example, considering the recent OSHA changes to ladder standards. Does the ladder included in the proposal explicitly specify OSHA 29 CFR 1910 Subpart D Approved? If one does and one doesn’t, you can’t assume the proposals are equal.

Coatings. Because steel rusts, the quality and proven longevity of the silo’s coating directly affects the silo’s service life and your return on investment. Not all silo coatings are equal, so ask if the supplier can provide objective third-party data on its coatings. Check if your supplier has used an independent testing lab to conduct salt spray, immersion, and falling sand tests on coated panels. These tests can identify how the coatings will stand up to corrosive and abrasive conditions. Ask if each supplier has silos in the field storing the same material you are planning to store and how long those silos have been in use.

Pricing specifics. Each proposal will be laid out differently than the last and may include different specific information. Check that the proposal conclusively defines the list price for materials and installation costs for the requested quantity.

-

- Price clarity. Check to verify that the total price is listed for materials, installation, and any extras for the entire project. If a proposal seems significantly cheaper than the others, there’s a chance that the supplier has listed it out as price per silo instead of the total project cost. If you have any questions or concerns about the proposal, contact the supplier.

- Steel price. Each supplier will factor in the volatility of steel prices differently. I’ve seen a lot of price increases lately because of tariffs imposed on steel imports and constantly changing steel costs. Most suppliers will honor a stated price for several weeks, even if a price escalation occurs during that time-frame. Others, however, state that the client will be responsible for any increase in the steel price between the date on the proposal and when the steel is actually procured. Note that steel is purchased when drawings are approved and the client releases the manufacturer to begin silo fabrication. Be cautious if a vendor inserts a low finished silo price to make the proposal look more attractive then reserves the right to raise the price whenever the supplier chooses to purchase steel, leaving you no recourse. When your supplier purchases the raw steel for your project should be based on a mutually agreed upon milestone date, such as when you release the supplier to start fabrication.

- Hidden costs. Keep an eye out for additional costs that aren’t reflected in the list price, as noted in the RFP’s fine print. Every supplier has to draw the scope line somewhere. So, wherever the line is drawn is where you make the comparison between proposals. For example, one supplier may offer crane rental, truck unloading, and erection supervision as standard while others may charge extra. Be sure each proposal spells out these extra services and each one’s cost.

- Price per pound. As discussed earlier, most suppliers will show the “estimated weight” of the total quantity and the total price for that quantity, shown in price/lb. However, to understand the strategic value in the offered price, weight alone isn’t a reliable basis for comparison, if you notice any silo weight outliers, it will be worth the effort to ask why. The weights listed on proposals aren’t measured in a consistent way or monitored by any governing body, so examine each proposal carefully as one supplier’s weight can vary from the others by as much as 40 percent, even though each set of calculations has been run through the same formulas. Simply looking at the total weight and price/lb won’t tell you enough to make an informed decision on a silo supplier. The weight used in these calculations can be difficult to accurately interpret because of a silo’s large size and the variations in measurement. For example, even if a supplier intends to use only 10 percent of a 100-pound sheet of metal in fabrication, the estimate listed may be based on the full 100 pounds. Avoid relying on these types of numbers because there are no standards governing how companies weigh their steel. What causes this weight variation? No single supplier has the answer but because “dead-load” on the quote is not a critical value in determining the yet-to-be engineered final design, don’t assume it’s accurate. That said, if you’re required to observe some level of valuation metrics, we recommend using price per ton or cubic feet of storage to make meaningful price comparisons. After all, you are buying storage capacity, not tons of fabricated steel.

Lead times. Some timelines can be deceiving. If you go with a less experienced provider, you may spend more time than anticipated agreeing on specifications and details before fabrication commences. Be careful when reviewing delivery dates and milestones because the clock doesn’t start until you’ve made a decision. Lead times on a quote are more of a reference point unless the calendar has been customized for your project with specific dates and milestones.

Remember, you’ll probably need to spend time on reviews and approvals before the clock actually starts. Many companies don’t schedule shop time until they have a confirmation in writing of what the customer wants. For example, a company may specify 8-10 weeks of lead time, but if the supplier lacks experience, doesn’t understand the application, or can’t present a layout that’s right the first time, you could spend several months on orientations before the clock starts.

Check and see if the supplier specified how long they need to complete the approved drawings. Many suppliers will just list how long they require to complete the manufacturing process, but that’s only part of the picture. Make sure you know the timeline for the whole scope of the project before moving forward.

It’s important to choose a supplier that has a proven track record. Investigate each company you get a proposal from independently to ensure they’re representing themselves accurately. Ask how many silos a supplier has in the field and for what applications. How many silos storing your specific material do they have in the field and how long have they been operating? Does the company specialize in a certain type of silo or application? How many years have they been in business? These are all key questions to ask to make sure you’re investing in your expansion with the right company.

References:

1. Jay Anzelmo, “What to Consider When Selecting a Silo” Powder and Bulk Engineering, November 2016

2. E.H Baker, L. Kovalevsky, and F.L. Rish “Structural Analysis of Shells” McGraw-Hill, 1972

Download “How to Identify Value in Competing Silo Proposals“, as appeared in Powder and Bulk Engineering, November 2018

Download our Supplier Tip, as appeared in Powder and Bulk Engineering, November 2018

CST Contact Information:

CST Industries, Inc.

Kim Mathis

Global Marketing Director

713-351-3769

kmathis@cstindustries.com

CST Industries, Inc.

Jay Anzelmo

Director, Dry Bulk Sales

913-982-7965

janzelmo@cstindustries.com