The TXI Riverside cement plant, located in the desert town of Oro Grande, California, is a terrific example of state-of-the-art cement plant design. It is also significant for several reasons. The plant is located upon the state-protected historical site of two old lime kilns dating back to the 1800s. It sits along historic Route 66, and very near to interstate highway 15 about 75 miles east of Los Angeles on the way to Las Vegas.

In 2005, the cement production facility that existed previously on the TXI site was expanded to incorporate a new processing system. AMEC of Atlanta and Zachry Construction of San Antonio were awarded the job of designing and constructing the facility.

In 2005, the cement production facility that existed previously on the TXI site was expanded to incorporate a new processing system. AMEC of Atlanta and Zachry Construction of San Antonio were awarded the job of designing and constructing the facility.

Significant in the California cement industry, this incredible plant is capable of manufacturing 6600tpd of clinker. The materials and equipment used in the design of the facility were delivered by companies located around the globe. The design is a preheater/precalciner manufactured and supplied by Polysius.

Natural elements – wind, heat and cold – presented challenges to the construction efforts. The location of the TXI Riverside cement plant was specifically chosen. The weather in Oro Grande is very dry, a great location for storing dry bulk materials and keeping them dry throughout the year. But the Santa Anna winds also blow strongly through this area, while winters are extremely cold.

Natural elements – wind, heat and cold – presented challenges to the construction efforts. The location of the TXI Riverside cement plant was specifically chosen. The weather in Oro Grande is very dry, a great location for storing dry bulk materials and keeping them dry throughout the year. But the Santa Anna winds also blow strongly through this area, while winters are extremely cold.

“Everything we handled was large and heavy, and required a crane to set. The constant winds required us to use tremendous care and patience,” said Ben Sims of Zachry Construction. The climate in the high desert is of one extreme or another – hot in summer and cold in winter – which also presented challenges.

“Attracting and retaining a workforce in that part of the country and in that environment was a challenge,” said Sims.California clean air requirements dictated that previously uncovered dry bulk materials be covered to reduce fugitive particulate emission.

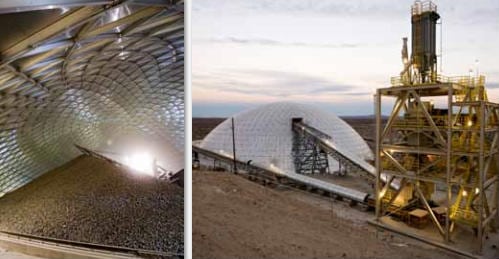

One of the most eye-catching additions to the new facility was a clear-span geodesic dome designed to cover up to 60,000t of limestone. This building measures 367’ x 90’ tall and was constructed by CST Covers.

The stacking and reclaiming equipment provided by Polysius was circular in design and the CST Aluminum Dome suited this perfectly. CST’s clear-span dome provided no interferences with the material handling equipment that was required inside.

The dome design included an opening at the top for a conveyor to bring in limestone.

A tunnel system below the covered area allows for material to be conveyed out of the dome underground. The building also includes two doors, one designed for a truck and the other a person-sized door.“The dome design was tremendously successful at managing dust and complying with clean air requirements, as well as providing a workable space underneath,” said Sims. “The dome design required a specialized erection process, including jack stands, cables and a computer-aided lift system, but despite the environmental challenges and wind, its installation was completed on time.”

Since its completion in 2008, the TXI Riverside cement plant has been tested at full capacity and has proven it operates successfully with the new equipment.

“We consider the overall construction effort for the entire plant to be a success,” said Sims.

Originally published in Bulk Storage January 2009

CST CoversCST Covers of Conroe, Texas is a global leading manufacturer and installer of custom-designed aluminum covers.

The company’s broad product offering includes aluminum geodesic domes, extruded and formed flat covers, truss and joist supported cover structures and custom architectural cover designs for use in a wide variety of applications.

CST’s covers are used for storage tank applications in water, waste water and petroleum as well as large dome structures for the storage of dry bulk materials. CST’s design, engineering and construction excellence are acknowledged throughout the cement industry and the world.