-

CST’s epoxy coated bolted steel storage tanks have been applied to thousands of applications in more than 125 countries throughout the world.

-

CST’s utilizes premium epoxy coating technology that provides maximum corrosion resistance and long tank life.

-

CST’s OptiBond™ Epoxy Coating System is derived from years of in-field experience and performance data.

Overview

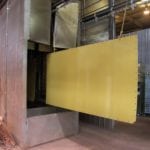

Coatings are the first line of defense in protecting the integrity of your assets. CST Trico Bond bolted epoxy steel tanks using the OptiBond™ coating process delivers outstanding performance and is the industry standard for epoxy durability, is corrosion resistance, and resists UV breakdown and abrasion. As the world’s leader in factory coated tanks, CST understands that the process by which a coating is applied is as important as the coating itself.

Tight manufacturing tolerances and numerous process controls are in place to ensure that the preparation of the steel, application of the Trico Bond coating and the curing of the coated material is unmatched. While other companies make claims about how proprietary the name of their epoxy product is, CST continues to invest in the OptiBond process to ensure it delivers superior performance and long-lasting results when applying CST Trico Bond coatings.

With more than 130 years of experience and over 250,000 field-tested applications around the world, no other manufacturer comes close to our level of knowledge of how to apply epoxy coatings and how they endure in some of the harshest environments. CST is proud to have our potential customers visit our ISO 9001:2015 Certified manufacturing facilities and see first-hand why CST’s coating processes are in a class of their own.

Benefits of Factory-Applied Coatings

CST applies all coatings in an ISO 9001:2015 Certified facility, under controlled environmental conditions using its proprietary OptiBond coating process to deliver the finest epoxy coating available in the storage tank industry. This eliminates weather factors that occur when applying coatings in the field after constructing a tank. There is no waiting for the weather to be within specific conditions in order to apply the coatings. Each step in the OptiBond coating process is carefully monitored so that inconsistencies in the coating can be detected in the earliest possible stage of the process. Completion of the tank can be performed in as much as 1/3 the time as alternative materials and methods. On-site delays due to weather are eliminated, and service can start earlier and return on investment begins sooner.

The CST OptiBond Coating System

CST Industries utilizes proprietary coating technology that provides maximum corrosion resistance and long tank life. Our experience has led to continuous technology and process improvements. The result is the finest epoxy coating available in the liquid tank industry. The OptiBond coating system is derived from years of in-field experience and performance data.

The OptiBond Coating Process:

Available Colors

Applications

Dry Bulk

CST provides flat panel, jack-built tanks, chime panel (CP) scaffold built tanks and factory welded tank designs, all capable of safely and economically being installed on every diverse site imaginable.

Industrial Liquids

CST’s TecTank™ storage systems are used to store a variety of liquid products including food, chemicals, mining fluids and slurries, pharmaceuticals and process fluids.

Water and Wastewater

When durable, economical above ground tank solutions are needed, CST TecTank storage systems are available with numerous water and wastewater process supplier’s products to deliver reliable and long-lasting liquid storage.

Fire Protection

With over 40,000 fire protection tanks manufactured, CST has proven experience in designing solutions that exceed NFPA 22, FM and USACOA requirements.

Petrochemical

CST’s roots are in the petrochemical industry manufacturing API monogrammed tanks. CST offers TecTank storage solutions for the frac process to oil storage and much more.

Power Generation

CST provides multiple liquid and dry storage tank designs from make-up water to fly ash and coal storage, CST can meet all your power generation tank needs.

Special Applications

Each application is unique, and each set of specifications is different. That is why CST has a team of material science engineers to help provide solutions to your unique application needs.

Photos

Featured Projects

-

Dry Bulk & Liquid Storage Tanks

-

Architectural Covers

-

Aluminum Domes, Reservoir & Flat Covers

-

Grain Tanks Help Whiskey Flow at Jack Daniels

In a world that moves too fast, it’s nice to know some people don’t believe in shortcuts. That’s the spirit behind Jack Daniel’s, America’s oldest registered distillery. Founded in 1866, Jack Daniel’s is an iconic brand that’s synonymous with whiskey. From its modest beginnings, it has grown into a global brand that is available in […]

-

CST’s Solution for the Francis A. Gregory Library – Aluminum over Steel

Situated in Fort Davis Park where a Civil War fort once stood, this iconic 25,500-square-foot structure is an elegant yet accessible gathering place for local residents – a re-imagining of what a library can be. The new Francis Gregory Library is stunning, beguiling, welcoming, and complements its leafy surroundings.

-

An Innovative Cover Solution Extends Reservoir Life

Styles come and go, and sometimes reappear. Take hats, for example. What’s fashionable in the 60s went out in the 70s but may come back a few decades later. However, when it comes to municipal water facilities, yesterday’s model is gone for good, replaced by a more contemporary, sustainable design.

-

Point Lisas, Trinidad Receives 2 State-Of-The-Art Glass-Fused-To-Steel Water Storage Tanks as Part of Nation’s First Water Recycling Project for Water Provision

Read Latest Case Study Here – Point Lisas, Trinidad Receives Two State-Of-The-Art Glass-Fused-To-Steel Water Storage Tanks

-

Above the Big Top: CST and Bell County, Texas Put on a Blockbuster of a Show

Even when the lead actor gets sick, the show must go on. Not only is that true in show business, but it’s also true with big entertainment venues. Keeping the lights on and the seats filled during an extended period of repairs is a testament to collaboration and intelligent design, and that’s the spirit behind […]

-

Odor Under Cover: A Solution for the Largest Wastewater Treatment Plant in Europe

Beckton Sewage Treatment Works is one of five wastewater treatment plants in the Thames Water network in the United Kingdom and the largest treatment plant in Europe. Headquartered in the London borough of Newham, Beckton Sewage Treatment Works serves 3.7 million people, mainly in north and east London. As part of a $309 million upgrade […]